Cement production is one of the most persistent sources of global CO₂ emissions, accounting for up to 8%.

Unlike some other industries, it is particularly challenging to decarbonize because emissions arise not just from burning fossil fuels but also from the chemical processes that turn limestone into clinker.

Despite the urgent need for change, the sector has seen slow progress.

Meanwhile, a combination of insufficient investment, limited strategic partnerships, and a lack of supportive policies has left many low-carbon innovations on the sidelines, preventing the industry from adopting solutions at the scale needed to meaningfully reduce emissions.

And so we caught up with 12 investors and founders to uncover where the opportunities lie, how they are approaching the toughest challenges, and the innovative strategies they are deploying to decarbonize one of the hardest-to-abate industries in the world.

Plus scroll on down for your go-to cheatsheet on 70+ rising stars in alternative cement to know.

DAC-Powered Decarbonisation

“The center of our approach is our CO₂ capture-to-concrete technology. We build modular direct air capture devices for indoor spaces that install in minutes, pull atmospheric CO₂ where concentrations are highest, and convert it into CO₂-captured materials that mix directly into concrete. Our technology is quickly deployable while avoiding the need for massive infrastructure and transforms buildings into carbon sinks by addressing both capture and concrete simultaneously.

We see major opportunities to scale across cities, capturing CO2 in transit hubs, commercial offices, and venues, meeting growing demand for both carbon dioxide removal and greener construction, while making climate tech a visible part of everyday life,” explains Julia Hestenes at Thalo Labs

Low-Cost High Performance MOF

“To reduce CO₂ capture costs in cement production, Decarbontek developed low-cost green adsorbents (MOF, cheaper than molecular sieves), shaped them into structured fibrous contactors, and integrated a renewable-powered, fast e-TVSA process—offering a scalable, energy-efficient path to industrial decarbonization.

We aim to cut CO₂ capture costs, enable easy retrofits for existing cement plants, and power operations with renewables—helping the industry meet emissions targets, comply with regulations, and deliver low-carbon products at scale,” explains Yong Ding of Decarbon

Software for Efficiency

“Our software addresses carbon emissions at the source by using predictive analytics to optimize the cement production process in real-time. This approach increases clinker efficiency within existing infrastructure, offering a scalable and cost-effective solution that avoids the massive investments required by traditional carbon capture technologies.

The opportunity lies in our product’s ability to impact the industry as it currently operates. The more producers gain confidence in reliable quality, the more empowered they will be to design and increase production of significantly lower-clinker cements. Our low-upfront, subscription-based model is attractive for a cost-conscious and low-risk market, driving faster adoption,” shares David Alós Shepherd of Alcemy

$1B for Low-Emission Cement

"Concrete Transition Capital is a catalytic investment platform committed to decarbonizing the cement and concrete industry. Myriad barriers to scaling low emission cement and concrete products have been identified and there has been no coordinated effort to address a central one: the lack of affordable capital and a deal team to derisk investment and scale funding of innovative materials production,” says Genevieve Rose Sherman of Concrete Transition Capital.

She then tells us that: “CTC flagship fund will deploy catalytic debt capital to crowd in additional commercial debt, support roughly $1Bn in new low emission cement and concrete facility construction and expansion by December 2028. This capital is expected to support approximately 1.5 million tons of new annual low emission material production, offsetting around 1.3 million tons of CO2 each year. Leveraging the expertise, operations, and sensitivities of diverse partners from the full cement and concrete value chain, our impact will be maximized by identifying and structuring financing for solutions that can scale quickly."

Modular Decarbonization for Cement

“Queens Carbon uses the same feedstocks as conventional cement—limestone and sand/clay—while partnering with cement producers to integrate its platform directly into existing plants. The process enables carbon-neutral Q-SCMs and/or novel Q-Cement at competitive costs and can operate on any energy source, including full electrification.

By deploying modular, scalable installations at existing cement plants, we enable producers to vertically integrate SCM production, meet demand for low-CO₂ materials, and reduce clinker use by up to 50%. Initial partnerships with major producers unlock rapid expansion across their plant networks through close collaboration, replication and future product flexibility,” explains Dave Gersholowitz, Co-Founder and CBO of Queens Carbon

Join the Reindustrialization Discussion

Deep Tech innovations are unlocking new frontiers in climate and industrial decarbonization and will take centre stage at the HackSummit at Newlab forging the future of steel, cement and materials discovery.

If you’re working in the space and looking to connect with other like minded builders, policy makers, investors and insiders, let’s make sure you’re a part of the conversation in New York, December 10-11th.

Solving the SCM Supply Demand Gap

“Supplementary cementitious materials (SCMs), e.g., fly ash from coal power plants, are well known as a cost effective way to cut carbon intensity, but they also have important technical properties for durability, making them a critical concrete ingredient. At the same time, conventional SCMs are disappearing as we transition away from the use of coal in power generation and steel production. At 2150, we’re excited about the commercial opportunity for startups addressing the growing pain point of SCM shortages,” notes Nicole Florack at 2150

Waste-to-value From Large-Scale Mine Tailings

Mine waste is a large-scale, low-cost, low-risk and high-grade source of industrial minerals that were not the target of the original mining operation. Industrial minerals are used in high-demand markets in cement, concrete, fertilizer and construction materials.

“BAIE Minerals application of proprietary sustainable technologies to detoxify, liberate and purify decarbonized industrial minerals and critical metals from mine waste. BAIE's process is effective at extracting more than 90% of the mine waste into saleable minerals and metals, representing a cutting-edge circular economy solution to pollution. BAIE Minerals is now at the pilot demonstration stage, with rapid deployment to commercial scale operations,” shares Mike Sullivan of BAIE Minerals

Turning Flue Gas into Profit

“At Sustained Carbon, we've designed the world's fastest enzyme to convert cement flue gas into calcium carbonate. Our financial models show this offers carbon capture as a profitable solution, not a cost.

We are working to become the new standard for profitable carbon capture and mineralization. We will soon open our pre-seed to build our prototype, proving a win-win solution for the cement industry,” notes Nicolas Fraser of Sustained Carbon

Circular Cement from Industrial Byproducts

“Carbon Upcycling creates high-quality, low-carbon cement materials from upcycled CO2 emissions and locally available industrial byproducts (steel slag, legacy fly ash, clays, and natural pozzolans). Our technology is uniquely capable of integrating with existing cement plants to utilize CO₂ directly from flue gas without pre-processing. Our materials extend plant capacity and cut cement’s carbon intensity, delivering a cost-competitive, scalable solution with resilient, circular supply chains.

We aim to establish long-term partnerships with cement manufacturers, concrete companies, and end-users to build resilient supply chains and accelerate low-carbon construction. We see an opportunity to scale globally by integrating with cement plants and driving market pull through specification influence, sustainable procurement, and monetization of environmental attributes such as carbon credits. This enables measurable emissions reductions at industrial scale,” Madison Savilow of Carbon Upcycling explains.

From Steel Slag to Solution

“Cocoon’s technology upcycles EAF steel slag into an SCM which matches the performance and price of GGBFS and fly ash, yet has 40% lower CO2 per ton. The supply of EAF steel slag is abundant and growing, and is already at over 200 million tons per year.

The demand to reduce the embodied carbon of concrete is growing, just as the supply of the commonly used SCMs (GGBFS and fly ash) is falling and at the same time steelmakers are switching to electric steelmaking, creating a huge volume of EAF steel slag, which is currently either landfilled or used as low-value aggregate,” adds Eliot Brooks of Cocoon.

Rebuilding with Waste Glass

“One way to decarbonize the built environment is to build concrete structures right the first time, with the best possible materials. With 15 years of research, testing, and large-scale deployments, we have optimized the conversion of waste glass into a consistent, high performing pozzolan to replace cement and produce exceptionally durable concrete at scale.

In the US, 2/3rds of consumer glass is landfilled. We will divert this resource from landfills with a network of electrified, zero water, zero chemical, local facilities providing a low carbon, circular solution to decarbonize buildings and infrastructure with the best possible concrete,” explains Louis P. Grasso, Jr., Pozzotive® Inventor at Urban Mining Industries

Cement Circularity

“Re-Bind advances sustainability by recycling agricultural twine into durable concrete fibers, reducing reliance on energy-intensive virgin materials. By enhancing concrete performance, our fibers lower cement requirements and extend service life, directly cutting CO₂ emissions. This closed-loop solution turns farm waste into climate action, creating stronger, greener, and more responsible infrastructure.

Re-Bind is seizing opportunities to scale sustainable concrete by replacing high-carbon fibers, building regional recycling hubs, and partnering with industry leaders for adoption. By aligning with growing demand for measurable carbon savings and EPDs, we create circular value from waste, cut emissions, and accelerate the shift toward low-carbon infrastructure,” concludes Chad Johnson at Re-Bind.

Cement Decarbonization at HackSummit

Brimstone is on a mission to transform heavy industry for a more sustainable and prosperous future. Its patented Rock Refinery® process co-produces multiple industry-standard materials—including ordinary portland cement (OPC), supplementary cementitious materials (SCM), and alumina—all from a single globally abundant, carbon-free rock.

The Brimstone process leverages the power of co-production, a tried-and-true strategy used throughout history, to produce industry-standard materials more efficiently, economically, and sustainably.

Recently, Brimstone announced a new commercial agreement with Amazon, reserving annual volumes of Brimstone’s low-carbon cement and SCM from its forthcoming plant.

Next up, Cody Finke, Co-Founder and CEO of Brimstone sits down with Rachel Slaybaugh, Partner at DCVC at the HackSummit to share his journey to tackle some of the world’s hardest-to-abate industries, starting with cement.

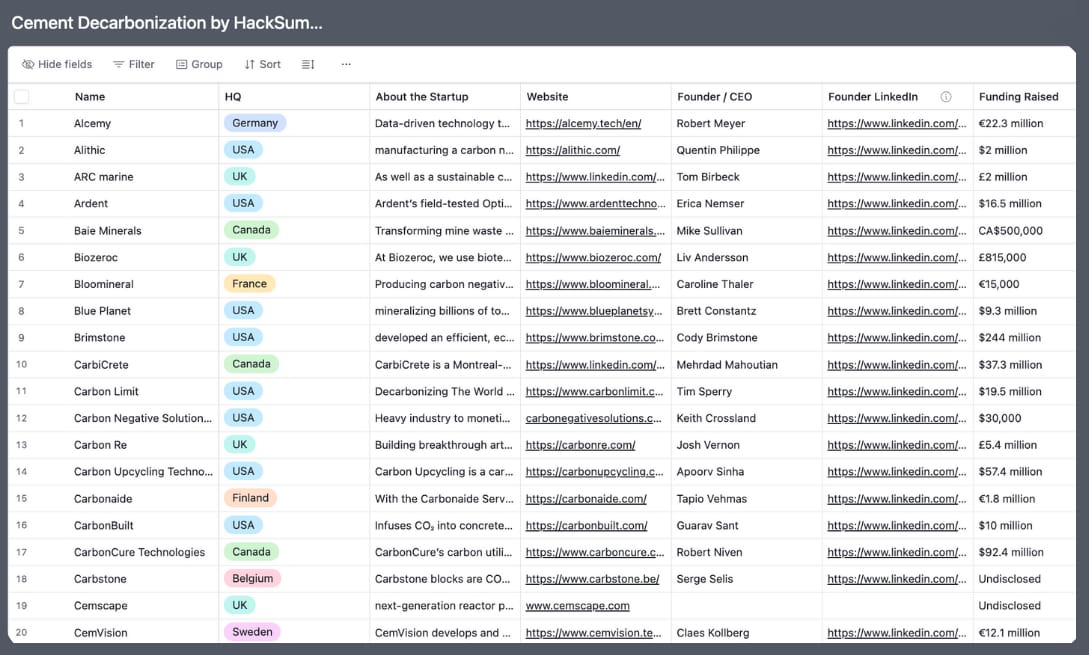

70+ Startups Working on Cement 2.0

Discover the full list of startups and scaling decarbonizing cement