As Deep Tech continues to evolve, it’s reshaping how proteins are sourced, engineered, and utilized, and holds the potential to revolutionize meat and ingredient alternatives, new materials and protein discovery.

Recent breakthroughs are enabling the development of more efficient, sustainable, and scalable protein production methods that address critical challenges across food security and climate change.

Here at Hack, we dive into 8 of the technologies at the intersection of Protein and Deep Tech and catch up with 15 experts in the space to hear their take on its potential to transform manufacturing, bioengineering, and food production.

Plus discover new names working at the cutting-edge of Protein x DeepTech as we reveal 220+ startups to know.

Want to hear more? Come and join us at the HackSummit in New York next month as we bring together 100s of investors, founders and operators at the cutting edge of Deep Tech. Use code COUNTMEIN to save 20% on your pass.

Let’s get started…

100 Protein Deep Tech Startups

We mapped 100 startups at the forefront of Protein Deep Tech across materials, mycelium whole cuts, cultivated meat, biomanufacturing and more.

Scroll on down to check out the full list with a go-to breakdown of 220+ startups.

15 Founders and CEOs weigh in on the Potential of Deep Tech for Novel Protein Technologies

🧫 Cultivated Meat

What: Cultivated meat is produced by cultivating animal cells directly and eliminates animals in the production process.

How: By cultivating animal cells and providing them with the necessary nutrients and growth conditions in bioreactors, these cells then develop into the same muscle and fat tissue found in conventional meat.

Accelerating Adoption: “For cultivated meat to reach its full potential, we need affordable and timely regulatory approvals to streamline market entry, ongoing advancements in scalable, cost-effective production and greater consumer education to build trust. Government support will also be crucial in driving policy changes and funding innovation to speed up adoption,” shares Paul Bevan at Magic Valley.

Overcoming Bottlenecks: “For cultivated meat to scale and become cost competitive, we need significant technological innovations in the underlying infrastructure that supports cultivated meat. A key example is the bioreactor. Developing new bioreactors that are more efficient, larger and more suitable for cultivated meat applications (rather than for biopharma) will be essential for the industry as whole to produce viable products,” notes Cecilia Chang of Mission Barns.

🔬 Fermentation-Derived Protein

What: Producing alternative proteins by using microorganisms like yeast, fungi, or bacteria to ferment raw materials into edible and non-edible protein products.

How: By leveraging fermentation to create a wide range of proteins across seafood, meat and dairy alternatives, as well as functional ingredients. One can distinguish between "precision fermentation", where the microorganisms are programmed to make the protein of interest vs "traditional fermentation", where one harvests the natural micro-organisms as protein-containing product, or in rare cases isolate a protein they naturally make.

Meeting Demand: "Fermentation offers the most exciting opportunity in alt proteins because it’s scalable, cost-effective, and produces clean-label products. As the market demand for sustainable, transparent, and nutritious alternatives grows, fermentation technology is poised to deliver high-quality proteins at scale, making it a key driver for market adoption," says Brittany Chibe at AQUA Cultured Foods.

🍭 Sweet Proteins

What: Derived from natural proteins and made via fermentation, advanced biotechnology produces protein-based sweeteners that are naturally sweet, low-calorie, and free from traditional sugars. Other approaches include technologies to reduce all types of sugars or enzymes to convert sugar with a protein.

Insight: “Precision fermentation technology is crucial for building stable, predictable supply chains for sweeteners and proteins, enabling sustainable, animal-free production. Key scaling challenges include cost efficiency, taste consistency, and navigating regulatory complexities, all requiring cross-sector collaboration to bring these solutions to market effectively,” highlights Darko Mandich at MeliBio.

🧬 Molecular Farming

What: Plant molecular farming is a form of alternative protein production that enables plants to express target molecules like animal proteins.

How: Companies are using plant molecular farming to produce cheese-making enzymes, animal proteins, growth factors for cell-based meat, pigments, and more.

Tell me more: “Traditionally, molecular farming focused on tobacco plants producing proteins, enzymes, and metabolites for the pharma industry. So, when molecular farming started being adopted in the food industry, companies mainly focused on hormones for cultured meat produced in tobacco. As the sector grows, we now see a much wider range of host organisms looking to produce different proteins,” explain Ido Eliashar and Maya Sapir-Mir of Polopo.

Unlocking it’s Potential: “Molecular farming holds the biggest potential for producing identical mammal-derived proteins, a particular challenge with complex proteins like casein. A single plant can grow all 4 sub-units of casein within one organism. That’s where molecular farming stands apart from other alt-protein methods,” says Dafna Gabbay of Finally Foods.

A Win-Win Technology: “Caseins are considered the “holy grail” of milk structure by the dairy industry. By developing animal-free caseins through plants instead of cows, it is possible to make almost any dairy product. The advantages of this technology is ”priceless” – cost effective in price and CAPEX and the scale-up is based on open fields and agriculture , instead of factories. This truly is a win-win technology: It benefits the consumers, the dairy producers, farmers, the health- and animal welfare-conscious flexitarians, and the global climate,” adds Daphna Miller of NewMoo.

Alpine Bio’s Magi Richani joins the HackSummit

Just Announced: Alpine Bio and Nobell Foods’ CEO and Founder Magi Richani joins us at the HackSummit in New York.

By using plants like soybeans and "teaching" them to produce non-plant proteins, Alpine Bio leverages the global farming and food infrastructure already in place.

During an intimate fireside chat, she will reveal how Alpine Bio is redefining Protein production with pioneering plant genetics and transforming plants into the world’s most scalable and efficient bio-factories.

Come and join us on December 12-13th for the ultimate Deep Tech gathering.

💨 Protein from Air

What: Whether they’re utilising carbon dioxide, hydrogen or methane, companies are using natural gasses, which occur all around us, to make protein by decoupling food production from farming.

How: Microorganisms convert captured carbon and other gasses into protein in a controlled environment. This protein can then be processed into nutrient-rich food products, offering a sustainable protein source that requires minimal land and water, reducing environmental impact.

Going Full Circle: “Instead of CO2 emission only being bad for society at large, CO2 can now be a “feedstock” in processes like e.g. photosynthesis in industrial applications for feed, food, cosmetics, fuels, chemicals. So in a circular economy, where we will continue to have biogenic CO2 as part of e.g. burning residual waste streams in Biogas plants then we can use that CO2 to turn back into valuable streams – full circle, no waste, no emission, low land and water use to feed a growing population. With Algiecel’s modular technology that is built into containers and placed by the CO2 emitters, we can make these solutions available in both developed industrial societies as well as the Global south,” shares Susanne Palsten Buchardt at Algiecel

👚 Materials

What: Material proteins are proteins engineered to create sustainable, natural polymers (e.g. surfactants, personal care ingredients, as well fabrics) that can replace traditional synthetics, animal-derived materials, and polymers across textiles, personal care, packaging and construction.

How: By leveraging fermentation or precision biology techniques to create proteins with specific structural or material properties, these proteins can be spun, moulded, or processed into fibers, films, and other forms, enabling the creation of durable, biodegradable materials that are both environmentally friendly and versatile.

Enhanced Performance: “Leveraging the power of AI to engineer proteins for scalability and material performance is the true breakthrough that enables sustainable biomanufacturing at scale across industries. Evolution has shaped proteins as high-performance biomaterials over eons for biological purposes; now, AI rapidly adapts proteins to meet the material requirements of our society. This powers a true bio-industrial revolution—designing materials that outperform conventional options while protecting our planet,” reveals Mitchell Duffy of Cambrium.

🧪 Cell Free Biomanufacturing

What: Enabling the production of proteins and biobased chemicals outside living cells by using only the cellular machinery required to synthesize molecules.

How: By extracting essential cellular components, such as enzymes, to build proteins and synthesize compounds in a cell-free system, this technique allows for faster, more flexible protein and biomolecule production, making it ideal for creating complex proteins and chemicals with high precision and purity.

Prioritizing Commercialization: “From my time at Zymergen, formerly one of the largest biomanufacturing companies, I saw how difficult and expensive scaling microbial processes was. So I realized we should focus on the core enzymes that do the sustainable chemical transformations instead. However once you leave the cell, the enzyme has a limited lifespan, and that's why at Cascade, we are commercializing our novel, cost-effective 'body armor' for enzymes to enable longer lasting, higher performing biocatalysts in industrial conditions,” Alex Rosay at Cascade Bio

🔍 AI Protein Engineering / Discovery

What: Designing, modifying, and identifying proteins with specific, enhanced properties for various applications, from medicine to materials and sustainable food production.

How: One part is about discovering existing proteins with ideal characteristics, the next step is to create something new-to-nature, or de novo. For this, one leverages ML models that "learn protein grammar" so that learning from the natural database, the AI can suggest designs that fill the requirements even better than nature has done.

Rapid Protein Access in Practice: “Omics and AI have generated vast protein hypotheses needing rapid testing. Despite fast gene synthesis, producing workable proteins remains a bottleneck, failing over 50% of the time and taking months. Nuclera's eProtein Discovery accelerates this process, enabling gene-to-protein results in just 2 days.” explains Cam Watson of Nuclera.

New Protein Design: “To date in biotech, we've been limited to repurposing proteins we find in Nature. This is essentially hi-jacking a plane, not first-principles engineering of a plane. These major advances in protein engineering—and the speed of progress being made—change this fact. We're starting to be able to truly design the molecular tools we want, whether that is new molecular sensors, vaccines, medicines, or totally new materials,” says Elliot Hershberg at NotBoring.

Unprecedented Speed and Cost: “AI can now rapidly identify scalable, natural, high-value ingredients, matching them to urgent health and sustainability needs – especially in food. This allows us to discover and scale beneficial proteins at unprecedented speed and cost, precisely when consumer demand and global challenges require these solutions,” Jasmin Hume of Shiru.

The Promise of AI: Thanks to AI, everyone can now design novel proteins using just their laptop. But testing these new protein designs in the lab can take months, requiring specialized skills and infrastructure that are very different from the software side. This lag between computational design and experimental validation slows down how fast you can iterate and design better proteins. At Adaptyv Bio, we're building a platform that allows protein designers to simply upload their computational designs and then have them rapidly validated experimentally in our automated wet lab,” concludes Julian Englert at Adaptyv Bio.

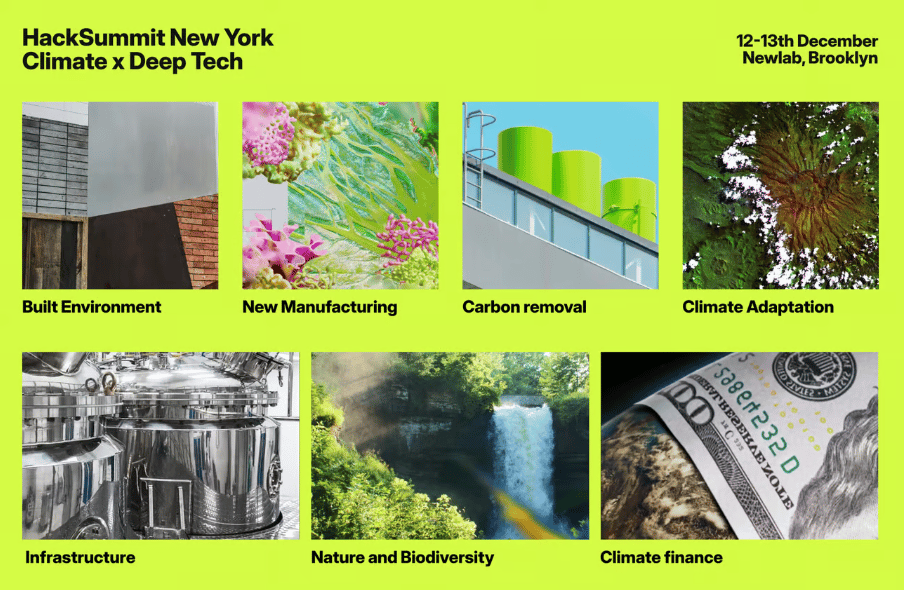

Meet the Climate Deep Tech Community IRL

Come and join us at the HackSummit in New York (12-13th December).

300+ industry mavericks and disruptors behind novel climate tech solutions are heading to New York next month for two days of networking and deal making across all things climate deep tech.

Ready to discover more? Head this way to see who’s speaking and what’s planned.

P.S. Code COUNTMEIN gets you 20% off your pass.

220+ Protein Startups to Know

We tracked over 220 companies in the space. Get to know the players working on solutions on the future of protein, and if there’s someone we’ve missed you can quickly add them here.